The main task of conveyors is reducing manual work when transporting materials in businesses while increasing efficiency at the same time. Chain conveyors are specifically used in moving heavy loads by employing the use of strong, continuous chains. They are mostly implemented using a double strand architecture. However, depending on the weight or width of what is being transported, chain driven conveyors may have a varied number of strands. In businesses, these conveyors are used in:

- Moving heavy products

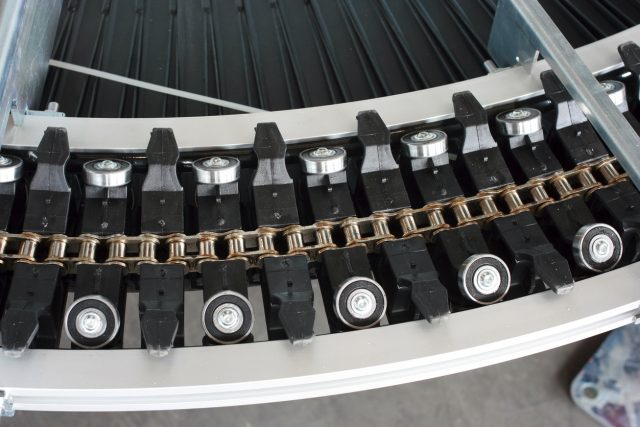

Chain conveyors are tough and strong. They can withstand the weight of heavy things such as engines and their components without slipping as rubber conveyor belts would. Also, when these heavy materials are placed on them, they do not compress or buckle as roller conveyors would. Instead, they provide grip and efficiently move materials around the business plant.

- Moving products through extreme temperatures

Chain conveyors come in handy in moving products through either hot or ice cold temperatures along the processing/ manufacturing plants. A roller conveyor might not be suitable for high temperatures because its components might expand unevenly and ruin its ability to roll. Similarly, a rubber belt roller might not be suitable for cold temperatures because rubber gets hard and stiff in the cold which makes it lose grip and therefore slip. This leaves chain conveyors as the most suitable option to operate in such conditions.

- Moving in indexing mode

Chain conveyors are the safest option when dealing with high precision processing. These conveyor units usually contain an index drive that moves the material to the exact position for further processing. An example is the precision link conveyor which is used by design engineers and machine builders to move engine parts to accurate positions for robot welding, automated inspection or other automated processing procedures.

- Moving products in variable speeds

The ability to change speeds on conveyors when moving materials is very advantageous. Chain conveyors can easily be fitted with a Variable Frequency Drive which can adjust the conveying speed to suit the speed at which other activities in the plant are being carried out. This adjustment can be done comfortably without worrying about slipping because sprockets grip firmly onto the chains regardless of external factors.

Additionally, chain conveyors have several advantages come in a variety of types which are majorly classified as pallet handling conveyors and factory handling conveyors, each with its own unique application area.

Advantages of chain conveyors

- Ease of installation

Chain conveyors are very easy to install. In fact, most chain conveyor manufacturers offer free installation services for every purchased conveyor to make it easier for you to begin operations immediately.

- Affordable

Their affordability is relative to their durability. Since they last for long with little maintenance costs, whatever the chain conveyor’s initial cost was, it is recovered eventually because it gives you a high return on investment.

- Flexible

Chain conveyors are very flexible. As the business operations scale upwards, more conveyors might be required. It is quite simple to modify and upgrade existing ones which reduces the overall scaling costs.

It is important to note that each conveyor system has its own application area where it performs best. Before buying such a system, consider these tips so that in the end you get the most efficient system that suits your business requirements.